Plastik enjeksiyon konveyörü, enjeksiyon makinelerinden çıkan sıcak plastik parçaları güvenli ve verimli bir şekilde taşıyan özel bantlı sistemlerdir. MB Makina’nın yüksek kaliteli enjeksiyon konveyörleri ile üretim hattınızı optimize edin. Dayanıklı, özelleştirilebilir modeller için hemen inceleyin!

Euro palet için rulolu konveyör sistemleri: Ağır yük taşıma, özel rulo aralıklı ve sigma profil şase. Verimli lojistik için gravity/tahrikli modeller.

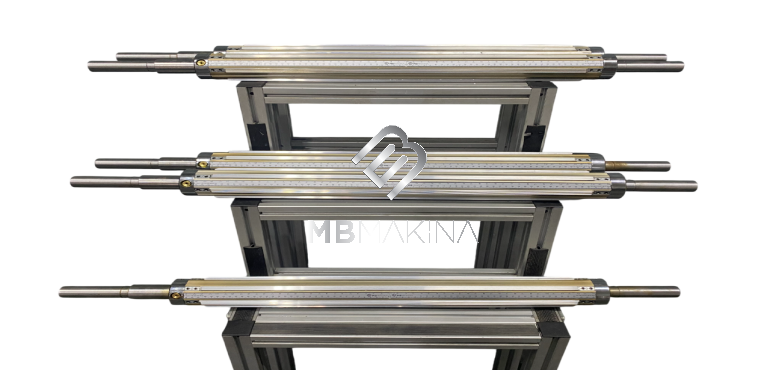

Alüminyum havalı şaft , farklı çaplarda ve boylarda üretilebilmektedir, 8 Bar hava basıncı ile şişirilen havalı şaflar , bobinin sıkışmasını alüminyum çıtalar ile sağlamakadır.

Alüminyum konveyör sistemleri , daha çok sigma profil ve ekipmanları ile imal edilmektedir. Alüminyum konveyör sistemlerinin bir çok avantajı olmaktadır. Hafif konstrüksiyon, paslanmaz ve demonte edilebilir.

PVC bantlı konveyör, polivinil klorür (PVC) malzemeden üretilen bantlarla çalışan bir taşıma sistemidir. Genellikle alüminyum veya çelik şase üzerine monte edilir ve motor-redüktör sistemiyle hareket eder. Bant yüzeyi düzgün, kaydırmaz ve hijyenik olduğundan, koli, paket, parça veya granül malzemelerin taşınmasında idealdir.

Enjeksiyon robot konveyörü nedir, nasıl çalışır? Avantajları, modelleri ve plastik üretimdeki rolünü keşfedin. Otomasyonla verimliliği artırın!

Elevatör konveyör ; Z Tipi elevatör konveyör ve L tipi elevatör konveyör olarak 2 farklı üretimi mevcuttur. Elevatör konveyörler ürünlerin aşşağıdan yukarı aktarılmasında kullanılır.

Plastik enjeksiyon konveyörleri çeşitlerini keşfedin! Robot konveyörü, L ve Z tipi elevatörler ile yolluk ayırma sistemlerinin avantajları ve kullanım alanları.

Tahrik rulolu konveyör , motor ile çalışan tahrikle dönen rulolardan oluşan konveyör sistemleridir. Zincir dişli rulo , triger kasnaklı rulo , v kayış rulo gibi farklı tahrik rulolu konveyör sistemleri vardır.

Avare rulolu konveyörler , ruloların serbest dönmesiyle çalışan, tahriksiz (motorsuz) taşıma sistemleridir. Ürünler, insan gücüyle itilerek veya hafif eğim (%3-5) verilerek yerçekimi kuvvetiyle ilerler. Rulolar genellikle galvaniz, paslanmaz çelik, alüminyum veya PVC malzemeden üretilir ve çapları 50-60-76 ve 89 mm arasında değişir.

Rulolu konveyörler (rulolu bant), avare ve tahrikli modelleriyle koli, palet ve ağır yükleri verimli bir şekilde taşır. MB Makina ROL50 serisi; modüler tasarım, özel ölçü üretim ve yüksek dayanıklılıkla lojistik, otomotiv, ambalaj sektörlerinde ideal çözüm sunar. Yerçekimiyle çalışan avare ve motorlu tahrikli seçenekler!

Konveyör, endüstriyel üretim hatlarında malzemeleri, ürünleri veya paketleri bir noktadan diğerine otomatik olarak taşıyan mekanik sistemlerdir. Günümüz fabrikalarında vazgeçilmez bir ekipman olan konveyörler, verimliliği artırır, iş gücünü azaltır ve üretim süreçlerini hızlandırır.

Havalı Şaftlar , miller üzerinde olan slotlardaki çıtalarla şaf çapını 7-10 mm arası arttırılarak bobinin şaft üzerinde sıkışması sağlayan ve hava ile çalışan elemanlardır. MB Şaft olarak farklı çaplarda ve boylarda müşterilerimizin teknik resimlerine istinaden özel üretimimiz bulunmaktadır.

Sigma Profil (Alüminyum Kanallı Profil) kanallı yapısının avantajları ile kaynaklı çelik konstrüksiyonların yerini almış alüminyum profil çeşidir. Sigma Profilin demonte (modüler) yapısı sayesinde istenilen parça ve Sigma Profiller birbirine hazır bağlantı elemanları ve aksesuarları ile kolay bir şekilde birleştirilebilmektedir.

Alüminyum sigma profil ihtiyaçlarınızı, yüksek kalite ve uygun maliyetlerle, siz değerli müşterilerimiz, üretici firma MB Makina olarak bizlerden temin edebilirsiniz. İstanbul içi ve çevresi alüminyum sigma profil ve bağlantı ekipmanı sevkiyatlarımız ambar veya özel nakliye firmaları ile itina ile yapılır. Sigma profil fiyatlarımızı öğrenmek için bizlerle iletişime geçmeniz yeterlidir.

Enjeksiyon makinalarına parelel veya altına konumlandırılarak, enjeksiyondan çıkan ürünlerin yukarı aktarılmasını sağlar elevatör konveyör sistemleri.

Rulolu konveyör sistemlerinde ihtiyaca özel , kauçuk kaplı rulo , polüretan kaplı rulo , galvaniz kaplı rulo vb birçok alternatif çeşit bulunmaktadır.

Havalı mil sistemleri sayesinde üretimde kayıp zamanı minimuma indirmek çok mümkün, hava ile çalışan sistemde bobine özel şaftlar

Sigma profil kanallı yapısı itibari ile ve bir çok bağlantı elemanlarının olmasından dolayı akla gelebilecek her türlü şase imalatı yapılabilir , bunu kaynak veya sonradan boya gibi ekstra ihtiyaçlara gerek duymadan yapmak isterseniz sigma profil en iyi çözüm olmakta.